We only supply the highest quality products

that have been fully tested and validated by our technical team.

CORES

They are typically low density materials that separate and stabilize the skin laminates and provide most of the shear rigidity of the sandwich structure. Sandwich construction enables high stiffness to weight ratios in composite structures.

RESINS

FIBRES

ADHESIVES

CONSUMABLES

MEL has carefully selected a complete range of process consumables specially selected to provide efficient and trouble-free production with all types of composite processing.

EQUIPMENT

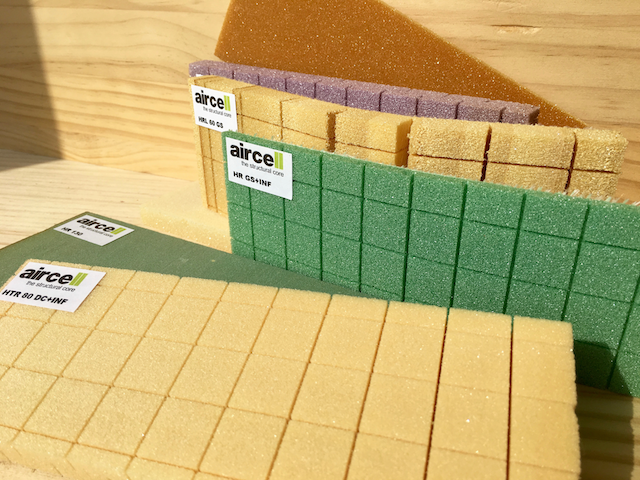

CORES

Core materials form the middle layer of sandwich-type composite structures. They are typically low density materials that separate and stabilize the skin laminates and provide most of the shear rigidity of the sandwich structure. Sandwich construction enables high stiffness to weight ratios in composite structures. SEE CATALOGUE

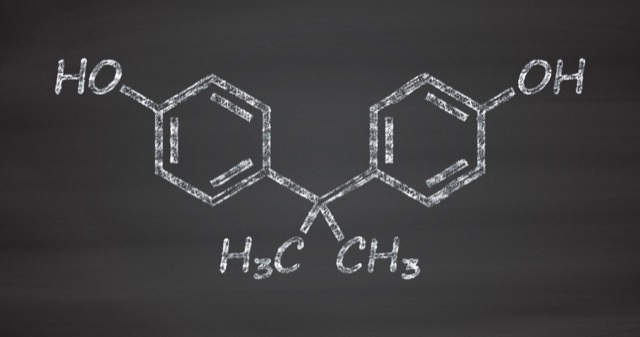

RESINS

Resins act as the support matrix for the fibres, impregnating them and forming the structure of the composite. Resins provide resistance to compression and create adhesion between the fibres and layers of the laminate whilst also keeping the fibres in the correct position and orientation. There are several types of resin available, the most widely used being polyester, vinyl ester and epoxy. They can be used in many different construction methods depending on the chosen process with options including hand or wet lamination, vacuum bagging, infusion and RTM or as prepreg materials where the resin is already combined with the reinforcement fibres. SEE CATALOGUE

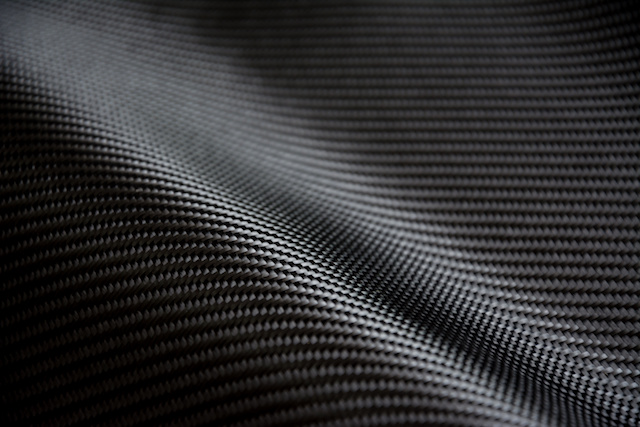

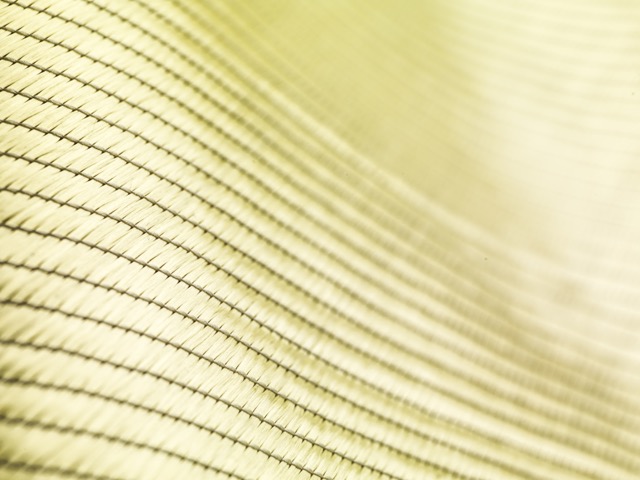

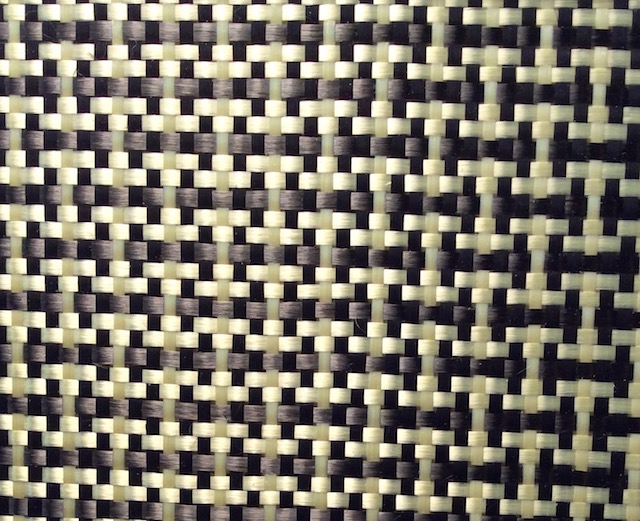

FIBRES

Reinforcement fibres are the main structural component that drives, among other things, the tensile strength of the structures. There are several types available, with glass, carbon and aramid fibres being the most commonly used in composites. They can be used directly as rovings or as woven, stitched multiaxial or unidirectional fabrics in a wide range of fabric weights and weave styles. SEE CATALOGUE

ADHESIVES

MEL Composites has a wide range of high-performance structural adhesive and sealants to cover all applications. SEE CATALOGUE

EQUIPMENT

PMEL Composites has a wide range of high-performance structural adhesive and sealants to cover all applications. SEE CATALOGUE

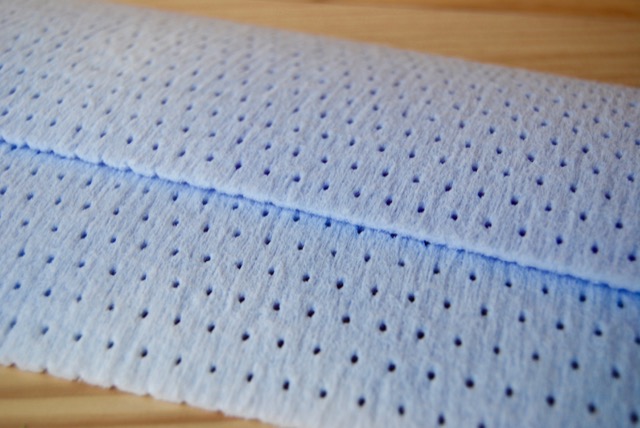

CONSUMABLES

MEL has carefully selected a complete range of process consumables specially selected to provide efficient and trouble-free production with all types of composite processing. SEE CATALOGUE

PRODUCT CATALOGUE BY CATEGORY

Aircell PVC is the foam sandwich core par excellence. The lowest resin surface uptake on the market combined with its high mechanical performance, low weight, high elasticity, thermal insulation and great chemical resistance make it the first choice for economical lightweight sandwich structures. The wide variety of densities, from 40 to 400 kg/m3, allows structures to be engineered and optimized as required. Aircell foam surface treatments can also be adapted to suit different manufacturing processes such as hand lamination, vacuum bagging, infusion and prepreg. If necessary, Aircell PVC can be thermoformed using heat and vacuum.

Available products:

Widely used in the aeronautical, automotive, marine, sports, and wind energy industries as well as in the reinforcement of buildings, carbon fibre offers the best mechanical performance for the lowest possible weight.

Various grades of fibres are available including High Strength, Intermediate Modulus and High Modulus fibres.

MEL Composites can supply:

- 1K - 50K fabrics

- Fabrics in aerial weights from 90 to 1200gr/m2

- Unidirectional carbon fabrics with glass or thermoplastic thread: 130 to 650 gr/m2

-Unidirectional tapes in HS &HM: from 1 to 20 cm wide and from 150 to 1600 gr/m2

- Stitched multiaxial fabrics: biaxial, triaxial and quadriaxial 300 to 1800 gr/m2

- Spread tow fabrics 15K, 24K and 50K: woven and unidirectional, standard or metallic from 30 to 400 gr/m2

- Tubular braids: from 5 to 150 mm diameter and from 7 to 330 gr/m

-Unidirectional expandable tube: 20 to 100 mm diameter

- Carbon-aramid hybrids

- Cured carbon plate 0.5 mm

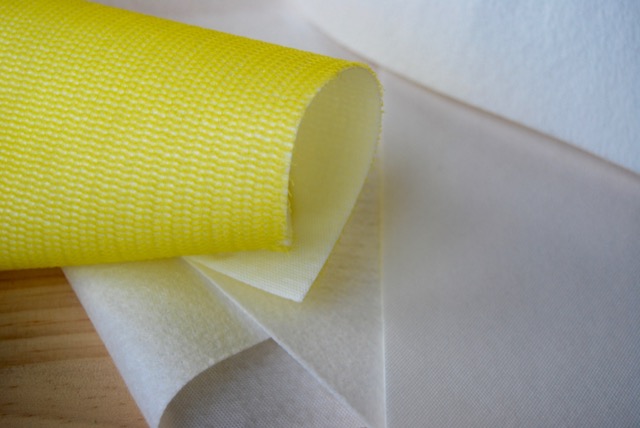

Renowned for their high resistance to abrasion and impact, aramid fabrics are often used in high-speed boats and other structures subjected to high impact loads, as well as in ballistic protection for armoured vehicles, helmets and vests.

Available formats:

- Fabrics: from 120 to 500 gr/m2

- Unidirectional

- Tubular and flat braids: from 10 - 50 mm and from 300 to 500 gr/m

U“End grain” balsa wood is a sustainably produced natural resource and one of the first materials to be used as a core for sandwich structures in composites. It provides high compression resistance and is suitable for higher temperature processing.

MEL offers Flexible – GS balsa materials that are cut into squares and supported by a fine fiberglass mesh. Density 150Kg/m3. Only supplied in complete boxes.

PET foam cores provide good mechanical performance and offer an economical, medium weight composite core solution. PET cores can be made from recycled plastic bottles and are available in various densities from 70 to 250 kg/m3. FR versions with good FST properties and low smoke emission are also available.

Available:

Cork is a natural resource that can provide excellent acoustic insulation and very good impact properties when used in composites. 100% recyclable, it is available in both sheets and rolls.

Available: NL10 with a density of 120Kg/m3

MEL offers an extensive foam core kitting service helping customers to reduce stock, eliminate waste materials and substantially reduce foam cutting and preparation hours; all whilst improving precision and quality. Once processed, the foam materials are delivered pre-cut and numbered according to customer drawings.

Once cut to the required thickness, foam cores can be processed with different finishes according to the customer requirements. They can also be supplied as a kit, with the necessary geometry and bevelled edges.

Coremat is typically used in hand laminating processes to add laminate thickness in structures where low weight and high strength are not key requirements.

In resin infusion processes, it can be used as a vacuum bridge and resin brake.

Available in 1, 2, 3, 4 and 5mm

Glass fibres are the most common composite reinforcement fibre due to their good properties and economical price point. Glass reinforcements are available in a wide range of different formats and weights. The stitched multiaxial fabrics MEL supplies have a DNV-GL certificate.

Available formats:

- Mat: 100 a 600gr/m2

- Fabrics: 200 a 1000gr/m2

- Combi fabrics - fabric + mat

- Unidirectional: 200 to 1000gr/m2

- Stitched multiaxial fabrics: Biaxial, triaxial and quadriaxial 300 to 1800 gr/m2

- Glass-aramid hybrids

- Prepregs

- Aluminized glass fabrics from 200 to 350 gr/m2

- Tubular braids

Prepregs are machine produced composite materials whereby the reinforcements are pre-impregnated with precisely controlled amounts of catalysed epoxy resin before the material are chilled to stop the curing process. They are stored at low temperature until the time of use and require heat and pressure for curing. Prepregs are ideal for the manufacture of high-performance composite structures using vacuum, autoclave and/or press processes.

Available formats:

- Carbon, glass, aramid, hybrid woven fabrics

- Carbon, glass, aramid, hybrid unidirectionals

- Stitched multiaxial carbon, glass, aramid, hybrid fabrics

- Alutex, Titantex, Cuptex, Goldtex coloured metallic fabrics

These reinforcements feature more than one type of fibre such as glass, carbon, aramid or other fibres, and offer a combination of properties based on their mixed construction.

Available formats:

- Glass - Aramid

- Carbon - Aramid

- Glass – Carbon

- Carbon – Polyester

- Carbon - Vectran

Polyester resin is the most economical option and is suitable for general purpose composite applications. Available in Orthophthalic (ortho), Isophthalic (iso) and Dicyclopentadiene (DCPD) based versions for hand lamination, infusion, RTM and casting processes. MEL also offer a wide variety of polyester gel coats, zero shrinkage resins for tooling and fire retardant resins. Materials certified by Lloyds, DNV-GL* are available.*

*Please check for specific certified product references

Polyester resin is the most economical option and is suitable for general purpose composite applications. Available in Orthophthalic (ortho), Isophthalic (iso) and Dicyclopentadiene (DCPD) based versions for hand lamination, infusion, RTM and casting processes. MEL also offer a wide variety of polyester gel coats, zero shrinkage resins for tooling and fire retardant resins. Materials certified by Lloyds, DNV-GL* are available.

*Please check for specific certified product references

Epoxy resins typically offer the highest mechanical, structural and adhesive performance in composite application and also provide a very high resistance to chemical attack.

MEL offers epoxy products for hand lamination, infusion, RTM, and casting processes, including some products certified by DNV-GL*

*Please check for specific certified product references

Hand lamination

Infusion and RTM: low viscosity products

Hot processes: in house prepreg

Clear systems: transparent resins for surf and windsurf boards

Fire retardant systems

Structural adhesives

High flexibility systems

Systems for wood

Colouring pastes

Epoxy foams from 170 to 600 kg/m3

Casting systems

Filling and profiling systems

Systems for high-humidity and underwater application

Gel coats

Fillers for epoxy including glass microspheres, phenolics, silica & cellulose microfibers, aluminum powder and graphite

Adhesives to fix dry fabric layers, cores and consumables in closed mould processes.

Tensor Grip: State-of-the-art spray adhesives, compatible with polyester, vinylester or epoxy resins. They do not affect the mechanical properties of the laminate.

Hot melt: High-adhesion hot melt adhesive that requires an electro-pneumatic gun to apply a glue line.

Patented, two-component highly structural methacrylate adhesives. They are applied with a manual, pneumatic or electric gun and static mixing nozzles.

SAF 30 5/15/45/MIB/LOT

SAF 150 5/15/45

SAF 400 5/15/45

Two-component, thixotropic adhesives that can be applied to horizontal or vertical surfaces. Various hardener speeds are available making these adhesives suitable for small as well as very large composite structures.

Isobond SR 1170

Isobond 735

Isobond SR 5030

Isobond SR5700

Isobond SR7300

Isobond SR5600

Thin perforated plastic films that allow the passage of air or resin in vacuum processes and facilitate easy removal of the consumable materials.

MEL Composites has a wide range of vacuum bags in stock from 50 to 120 microns thick and in widths of up to 16 meters; flat or tubular. Vacuum bag selection must take into account the shape of the part and the process temperature.

Flexible infusion mesh is used to help resin flow and air removal during the resin infusion process.

Also known as “tacky tape”, sealant tape is a soft, flexible adhesive tape used to seal the vacuum bag to the mould. MEL offers sealant tapes for temperatures from 90 to 200˚C

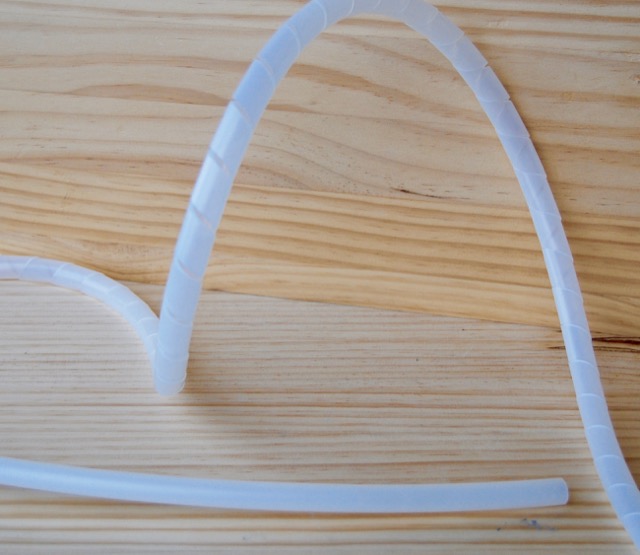

This consumable resin channel helps the distribution of resin under the vacuum bag and can also be used for perimeter vacuum lines. Available in various diameters, its 3D internal structure will not collapse under the pressure generated by the vacuum and the flat profile leaves no imprint on the finished composite part.

This vacuum channel is used in areas in contact with the infusion resin as its air-permeable membrane allows it to maintain vacuum and air removal at all times.

MEL supplies a range of polyethylene tubes in various diameters for vacuum processes, both for resin supply and for air removal. These tubes are economical whilst also being able to withstand the temperatures and pressure generated by the vacuum without collapsing.

Vacuum tight valves and connectors allow technicians to easily control the supply of resin to the infusion. They are available in various diameters to suit a wide range of pipe sizes.

Tightly woven peel ply fabrics are easily removed from the cured composite laminate and provide an ideal surface to continue laminating or painting.

The Compoflex range of products allow significant savings in time and materials by combining the functions of peel ply fabric, breather, perforated film and infusion mesh in a single product.

Available in sheets from 0.5 to 5 mm.

Resin pipe bases These pipe bases, available in several different styles and sizes, allow the connection of polyethylene tubes to the resin or spiral channel, facilitating the sealing of the vacuum bag.

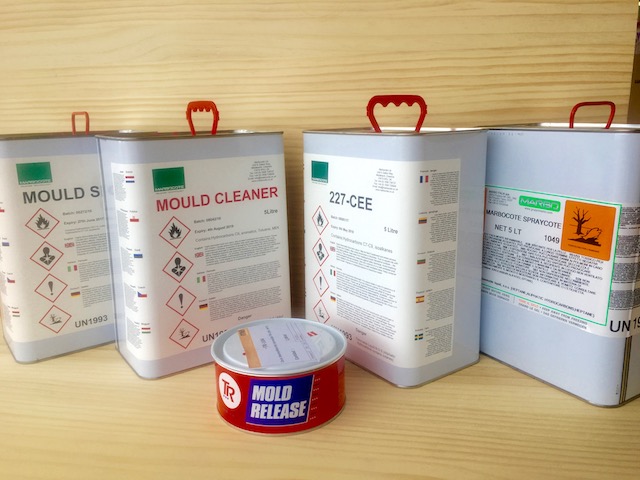

Cleaner to degrease and prepare the mold.

Sealer for new clean moulds.

Release agent in the form of manual wax.

Semi-permanent liquid mold release agent applied manually or by spray gun.

Beather fabric is a highly absorbent fabric that allows air removal in vacuum processes and soaks up any excess resin in the manufacturing process.

Ultrasonic air leak detector to check the integrity of the vacuum bag.

Complete set of cutter with battery, charger and spare blade; for cutting fabrics quickly and precisely.

Infrared digital thermometer, with laser pointer; to monitor the evolution of the resin, mould and workshop temperature during manufacturing.

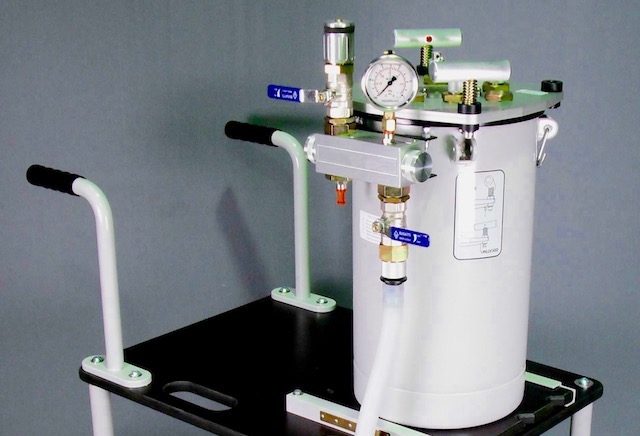

Simple resin trap, with a lid with 4 locking clamps.

This resin trap does not have a viewing port.

A vacuum regulator and vacuum gauge can be added if required.

Cup viscometer, with 3 or 4 mm caliber, for measuring resin viscosity.

Industrial electric gun with compressed air feed for the application of hot melt glue cartridges. It is supplied in a storage box and comes with an extension cable and support base.

Sprayomer Elastomer bags are custom-made on the mould and can be reused numerous times, reducing production time and the necess materials. They do not contain silicones.

MEL Composites can provide all the equipment necessary for manufacturing together with the technical support for the manufacture of reusable vacuum bags for every requirement.

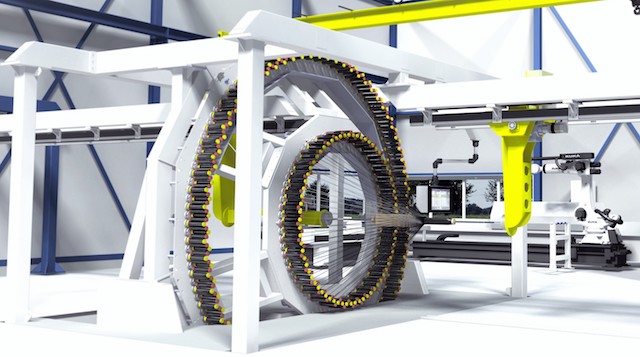

Eurocarbon, with more than 15 years of experience in the "overbraiding" sector, can manufacture both braid manufacturing machines and turnkey "overbraiding" machinery, as well as carry out the complete development of preforms and the transfer of technical know-how for any braiding application.

MEL Composites supply the Vacmobile range of vacuum solutions for composites. This highly versatile range is made up of several different components including vacuum pumps, regulators and resin traps and can be adapted for composite production facilities of all sizes.